The pipe end and valve end are in equal diameter, The valve end is beveled to match with the thickness And bevel on the pipe and the two ends are butted to the pipeline and welded

Rasaii Flow Lines Private Limited

PTFE Sleeved Plug Valve Manufacturers In India

1. Designed for smooth and efficient fluid handling of corrosive mediums

2. Provide effective sealing even in low pressure service

3. These are primarily On/Off valves

4. Design variation exist that makes it suitable for throttling application

5. Our Sleeved Plug Valves are truly fit and forget valves

1. Flanged End

- RFL flanged end SPV comes with Raised face, Flat face, Small Groove, Large groove, Ring Type Joint Flanges as option.

- SPVs are flanged as per ASME B 16.5; BS 10 Table ‘D’, ‘E’ & ‘F’;

- Raised Face – Allows use of wide combination of gasket designs and commonly used in process plant application. The main purpose of RF flanges is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint.

- Flat Face – The gasket surface and bolting circle face are on the same plane. Hence the whole face of the two flanges ensure full contact.

- Ring Type Joint – They are predominantly used in high pressure and high temperature service. The flanges provide metal to metal sealing when the metal ring is compressed between the flanges using bolts to create a tight contact between the grooves.

- Tongue and Groove – Here the flanges must be matched. One flange face has a tongue, raised face while the groove i.e the mating flange has a matching depression machined on to its face. Tongue and Groove facings are standardized in both large and small types.

2. Screwed End

- Threaded connections provide a streamlined and compact connection between the pipe and valve.

- The valve generally has a female threaded end connection in which the male threaded pipe fits.

- The end provides tapered or straight pipe threads.

3. Socket weld

A socket is provided in the valve ends in which pipe is Inserted into the socket and welded. They are normally Used for small pipeline

4. Butt weld

1. Bare Stem

RFL flanged end SPV comes with Raised face, Flat face, Small Groove, Large groove, Ring Type Joint Flanges as option.

SPVs are flanged as per ASME B 16.5; BS 10 Table ‘D’, ‘E’ & ‘F’;

2. Wrench Operated

Sleeved plug valves are operated in Quarter turn. Hence for low torque applications a wrench provided for valve operation.

3. Gear Operated

For High torque applications Gearbox with hand wheel is provided to Operate the Valve.

4. Actuator Operated

RFL flanged end SPV comes with Raised face, Flat face, Small Groove, Large groove, Ring Type Joint Flanges as option.

SPVs are flanged as per ASME B 16.5; BS 10 Table ‘D’, ‘E’ & ‘F’;

5. Deadman Handle Operated

These are also known as spring return handle valves. The special handle ensures that the valve will always “spring return” to its original starting position, when hand / manual effort is released. This type of valve finds vast application in critical service were the valve has to be quickly returned to the original position once a manual operation is completed. These valves assure safety and avoid unnecessary wastage, of costly medium, whenever the valve is allowed to remain in partially opened or closed position, inadvertently.

6. Extended Stem operated

Extended stem into “RFL can supply valves with extended stem. These valves are predominantly used in places where the valves are not in close proximity with the operator eg: valve located under water, toxic environment, hot pipe line”

1. Cage type

RFL’s Sleeved Plug Valves with caged plugs are mainly used in throttling application and in high pressure drop service. These valves have metal to metal throttling and minimizes turbulence for fluids with high velocity.

2. Multi ports (3 way & 4 way)

RFL can offer multi-port valves. We regularly supply 3-way, 4-way valves. Multi – port valves are space saving valves that simplify the distribution system and reduce risk of leaks. These valves can be used to handle multiple fluids or to divert the flow of fluid from one direction to another.

3. Reduced bore / Rectangular Port

Rectangular port corresponds to 70% of internal process pipes area

4. Full Bore

Full Bore Valve they have a bore which is fully circular throughout the valve, including the obturator port. In pipeline fluid transportation, accumulation of dirt and foreign particles can lead to clogging and fluid contamination, especially in oil and gas industry, crude oil pipelines. This calls for PIGGING- Pipeline Inspection and Gauging.

5. Inverted/Pressure Balanced Type

The Inverted Sleeved Plug Valves completely eliminates the jamming Possibility of Plug with Valve body sleeves. The self-weight of the plug would provide always a dis engagement tendency, which is ably countered by an adjustable and supporting screw at the bottom.

1. Fire safe – API 607 / API 6FA / ISO 10497

RFL’s fire tested sleeved plug valves are in accordance with API 607 / API 6FA / ISO 10497 standard. These valves have an additional sealing feature to prevent leakage after the PTFE sleeve and other soft sealing parts are totally destroyed by fire.

3. Fugitive Emission – API 641 / ISO 15848 – RFL Enviro

For High torque applications Gearbox with hand wheel is provided to Operate the Valve.

4. Severe service SPV with Superior Emission control – RFL Enviro 2.0

RFL flanged end SPV comes with Raised face, Flat face, Small Groove, Large groove, Ring Type Joint Flanges as option.

SPVs are flanged as per ASME B 16.5; BS 10 Table ‘D’, ‘E’ & ‘F’;

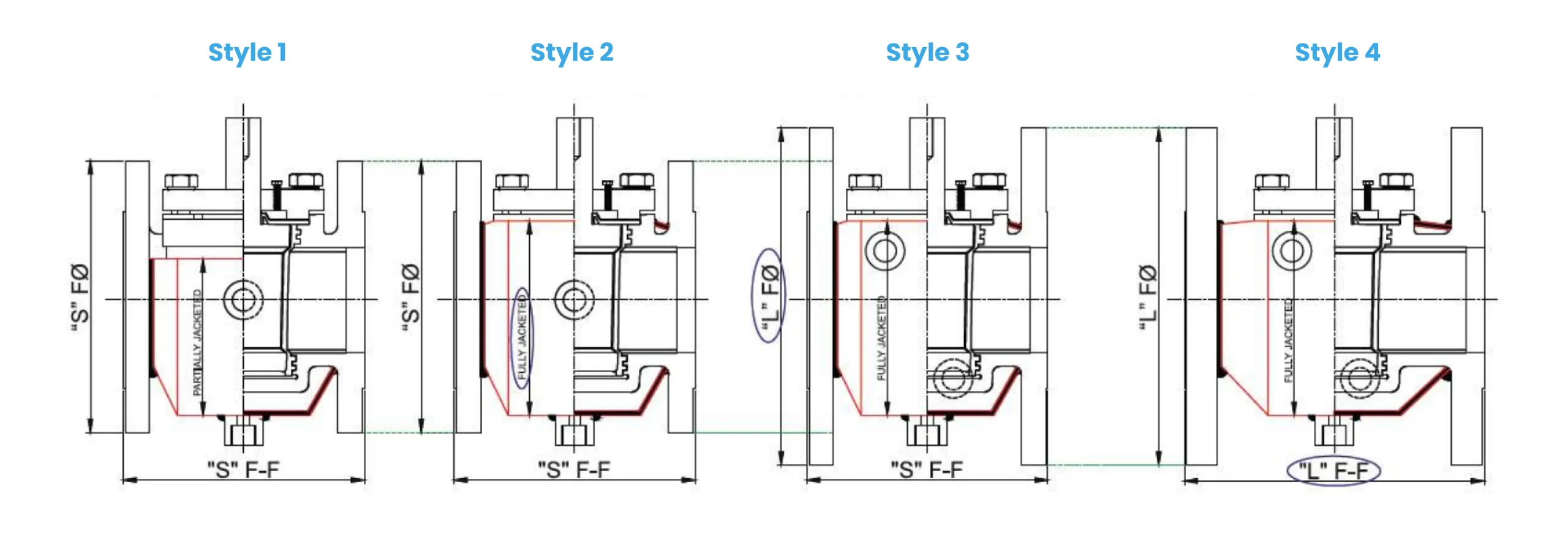

Jacketed Valves

Jacketed valves are mainly used in applications where the process temperature should be maintained in the valve to keep the process media as fluid and to maintain the flow. To facilitate this process jackets are provided through which hot liquids/gases are circulated.

RFL’s jacketed valves are broadly classified in to two types,

a. Partially jacketed

b. Fully jacketed

- Style 1 : Partially Jacketed Valve

* Valve and Corresponding flanges are of same size - Style 2 : Full Partially Jacketed Valve – Jacket extends till cover plate

* Valve and Corresponding flanges are of same size - Style 3 : Fully Jacketed Valve – 1

* Valve with oversized flanges and face to face corresponding to valve size - Style 4 :Fully Jacketed Valve – 2

* Valve with oversized flanges and face to face corresponding to over size flange size

Sleeved Plug Valves

Sleeved Plug Valves